ViriDyn is building a better world through continuous innovation in essential chemistries.

Expertise + Sustainability = Progress

-

ViriDyn’s central missions are:

Continuous development of innovative chemistries, including PFAS-free alternatives, that address critical engineering challenges.

Practice and promote the responsible, sustainable use of fluorinated chemistries for essential applications only.

Develop and deploy innovative methods to reclaim PFAS from contaminated waterways and to recycle PFAS into non-virgin fluorochemical materials.

-

ViriDyn specializes in high-performance monomers and polymers for nano-coatings (0.1 to 20 µm), plastic additives, repellents, surfactants and other advanced surface treatments, including superhydrophobic, hydrophobic, oleophobic, and anti-corrosion formulations.

-

ViriDyn’s advanced chemistries play essential roles in aerospace, automotives, electronics, defense, filtration, industrial automation, life sciences, medical devices, oil & gas, telecommunications and SATCOM.

Essential Chemistries for Advanced Industries

Hydrophobic, Oleophobic, Superhydrophobic

-

ViriDyn coated membranes repel water and oil, while allowing passage of air, gases, and sound. ViriDyn coatings can achieve oleophobicity up to grade 8.

Diverse applications across diffusion barrier, filtration, venting, and membrane systems:

Automotive headlamps.

Architectural, Building & Construction Membranes for waterproofing & moisture control.

EV Motors, Powertrains, Batteries & Battery Management Systems (BMS).

Engine oil sensors, Gas sensors, Smoke sensors, Tank pressure sensors.

Medical devices, catheters, IV filtration, suction-related apparatus.

Moisture protection for consumer electronics, smartphone speaker & microphone vents, headphones, smart watches.

Water purification & filtration systems.

Vented packaging for chemical industries, oil & gas filtration, fracking water organics clean up.

-

ViriDyn’s Hydrophobic and Oleophobic nano-coatings protect high-end consumer electronics both internally and externally. Achieve up to IP69 rated protection.

ViriDyn coated vents and meshes provide waterproof protection from moisture and contaminants ingress for smartphone speakers & microphones, bluetooth headphones, portable speakers & household IoT devices, sound systems, smart watches, and more.

ViriDyn coated circuit boards are corrosionresistant, chemicalresistant & waterproof, protecting smartphones, smartwatches, and other high-end portable electronics.

ViriDyn coated touchscreens and lenses are anti-smudge, anti-fingerprint, and abrasion resistant up to 9H hardness while maintaining full optical transparency.

-

ViriDyn’s oleophobic coatings and plastic additivescreate low-retention surfaces that repel blood, biofluids, earwax, and lipids.

ViriDyn’s medical-grade coatings are important in design of medical devices, drug delivery devices, microfluidic devices, and surgical instruments and scopes.

ViriDyn’s oleophobic coatings are essential for venting membranes used in healthcare applications such as catheters, IV filter vents, suction-related apparatuses, and instruments.

ViriDyn’s low-retention plastic additives are used to make essential everyday medical & life-sciences disposables including pipette tips and tubing.

-

ViriDyn hydrophobic & oleophobic conformal nano-coatings protect printed circuit boards, connectors, wiring and other electronics components from:

Moisture

Humidity

Corrosion

Chemicals

Salt-Fog

Tin-Whiskers

Contaminants

Environmental Hazards

ViriDyn conformal nano-coatings offer the following advantages:

Waterproofing

Up to IP69 ratings

Mil-STD 810 protection

Masking-optional

Excellent thermal management

Easy reworkability

QC/QA compatible (UV tracers)

Easy application (dip, spray, spin, flow)

Drop-in replacements for 3M Novec Electronics Grade Coatings (1700, 1900 series).

ViriDyn offers the industry’s most advanced hydrophobic-oleophobic nano-coatings for SMT stencils.

Benefits include:

Chemical resistance to stencil cleaning solvents

Improved solder-paste release

Improved transfer efficiency & print quality

Reduce underside cleaning

Reduced solder bridging

Abrasion resistance for increased stencil longevity & printing efficiency.

-

ViriDyn fluorinated electronics grade coatings are excellent drop-in replacements for 3M Novec 1720. Coatings dry to a thin, transparent, permanent film with excellent hydrophobic and oleophobic properties.

No volatile organic compounds (VOCs). Low global warming potential

Highlights:

Easy application and processing - air dries in seconds (thermal cure for best performance).

Adheres to a variety of surfaces including glass, metals and metal oxides.

Excellent anti-wetting, anti-stiction and anti-migration properties.

Optically transparent. Contributes no additional haze. No loss of clarity.

Applications:

Easy clean surfaces:

glass flat panel displays

mobile electronic device components

semiconductor photomasks

-

ViriDyn hydrophobic & oleophobic conformal coatings are essential for protecting ruggedized electronics from short circuits, moisture, dust, chemicals, and other environmental hazards.

These coatings are essential for the dependable performance of mission-critical electronics systems in the field.

ViriDyn hydrophobic & oleophobic conformal nano-coatings protect printed circuit boards, connectors, wiring and other electronics components from:

Moisture

Humidity

Corrosion

Chemicals

Salt-Fog

Tin-Whiskers

Contaminants

Environmental Hazards

ViriDyn conformal nano-coatings offer the following advantages:

Waterproofing

Up to IP69 ratings

Mil-STD 810 protection

Masking-optional

Excellent thermal management

Easy reworkability

QC/QA compatible (UV tracers)

Easy application (dip, spray, spin, flow)

Drop-in replacements for 3M Novec Electronics Grade Coatings (1700, 1900 series).

-

ViriDyn’s superhydrophobic, RF-transparent coatings reduce signal loss caused by rain, ice and snow.

Essential protection for:

Marine and Ground-based Microwave Antenna

5G antenna, Massive MIMO Antenna Arrays

Telecom Backhaul Links for Remote Access Systems

Flat Panel Antenna (Ku-band, Ka-band, LEO, GEO)

Electronically Steered Antenna (ESA) systems

Enterprise & Defence Radar systems

Wind and Radiometric sensors.

Mid-Path Passive Reflectors and Repeaters.

-

ViriDyn’s hydrophobic & oleophobic coatings protect sensors and lenses from:

Condensation, Humidity, Moisture

Corrosion & Salt-Fog

Harsh Chemicals

Fouling, Smudging & Abrasion

Additional Performance Features:

RF-Transparency

Optical Transparency

Impermeability

Use Cases Include:

Anti-fouling, biofluids repellency for surgical scopes.

Abrasion resistance for optical lenses.

Condensation elimination for ultrasonic sensors.

-

ViriDyn’s superhydrophobic, hydrophobic, and oleophobic nano-coatings create essential reliability across aerospace, maritime & defence applications:

Protect electronics components from corrosion, moisture, tin whiskers.

Prevent signal loss and disruption from rain-fade by protecting radomes, radar, and antenna.

Protect sensors and lenses from harsh operating environments.

SUPERHYDROPHOBIC

-

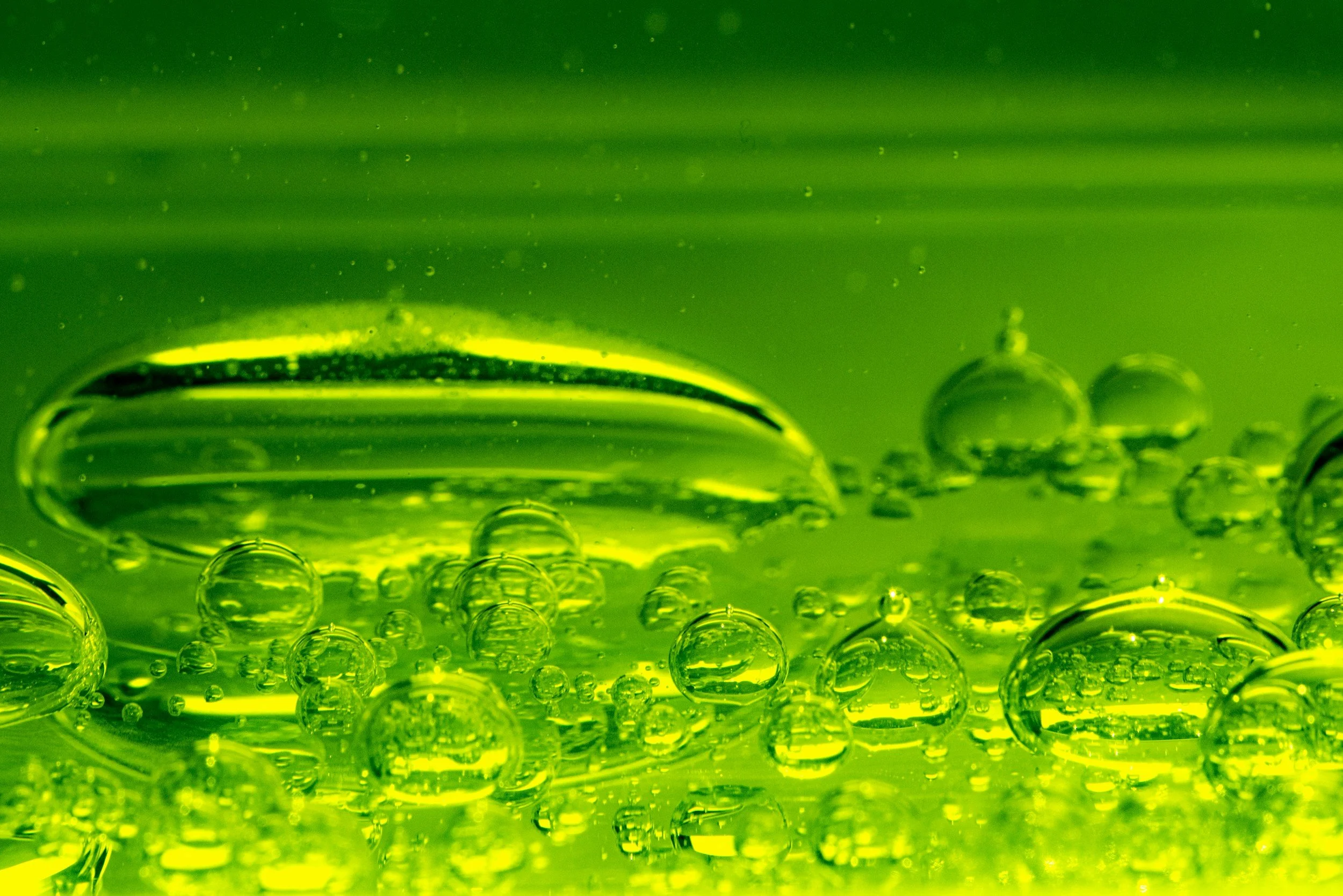

A super-hydrophobic surface has a contact angle to water that is >150 degrees. The contact angle for water on smooth solids cannot exceed approximately 130°, which is the limit for chemical hydrophobicity.

To alter a hydrophobic surface to create a one that is super-hydrophobic, the surface must be roughened by the addition of micro or nano particles.

Two criteria define super hydrophobicity:

The surface has a very high-water contact angle (>150°) and;

The surface is micro or nano structured.

Creation of a surface with a greater than 150° contact angle to water is due to the air entrapment in the gaps of the rough structure. It is important to remember a super-hydrophobic surface is therefore a composite structure of air and solid in combination with the presence of low surface energy components on the roughened surface.

-

The phenomenon of super-hydrophobicity and related wetting mechanisms are attractive scientifically, but also from the industrial point of view, where extreme water repellency is desired. Articles with super-hydrophobic surfaces shed water very efficiently, carrying with it readily dissolved and wetted particulates.

Another advantage of a super-hydrophobic surface is that it dramatically lowers the resistance to water flow at that surface. As the affinity of the surface for air or other gas is much higher than for water, the resistance to water flow can be primarily defined by the viscosity of the water with air or other gas rather than the solid surface. In this way a superhydrophobic coating lowers the coefficient of friction or the drag.

In addition, a very important property of a superhydrophobic coating is increased ice and snow repellency.

-

In spite of numerous scientific papers on super-hydrophobic coatings most of the commercial super-hydrophobic surfaces have their limitations. Since a super-hydrophobic surface is a composite structure of air and solid in combination with the presence of low surface energy components on the roughened surface, this type of surface can be damaged due to abrasive forces which in turn reduce the level of hydrophobicity, limiting many commercial applications of super-hydrophobic coatings.

-

Just comparing the contact angles of water to hydrophobic and super-hydrophobic surfaces you would easily think that having a super-hydrophobic surface would be better than a hydrophobic surface. However, there are other types of properties that need to be considered in deciding between a super-hydrophobic and hydrophobic surface such as abrasion resistance, durability, and transparency.

Sometimes an abrasion resistant hydrophobic coating can offer more protection from water and moisture than a super-hydrophobic coating. If transparency is desired to protect against moisture, then a hydrophobic coating is generally more robust and less expensive.

-

Roughened and particle containing super-hydrophobic surfaces effectively repel water but do not always repel ice. The problem is the mechanism of action of super-hydrophobic coatings. In humid and cold conditions, water droplets can form within the rough super-hydrophobic coating by condensation. After condensation, water droplet nuclei create water-loving and ice-loving patches. In high humidity cold conditions super-hydrophobic surfaces can lose their hydrophobic and icephobic properties.

A surface that has ice adhesion strength of less than 100kPa is considered icephobic or anti-icing. Unfortunately, ice adheres very strongly to many structural materials – aluminum, for example, has ice adhesion strength of 1600kPa.

Since ice is frozen water, a great deal of research has been conducted on making icephobic coatings by increasing water repellency. Newer approaches based on interfacial cavitation using rubbery elastomers have been shown to create more durable icephobic materials. Even a small amount of force can deform the rubbery surface, breaking the solid free.

-

VIRIDYN SH-2 is a 2-step superhydrophobic coating used on marine and ground-based microwave antenna, 5G antenna, radomes and other telecom gear to prevent rain fade. VIRIDYN SH-2 also significantly reduces snow and ice accumulation.

To learn more about VIRIDYN SH-2, click here or visit ViriDyn’s Products page.

ViriDyn also offers VIRIDYN SH-1, a 1-step superhydrophobic coating, click here or visit ViriDyn’s Products page.

If you have a technical challenge that could be solved with a superhydrophobic coating, contact us. We have either already developed it or can use our expertise and technology to engineer a specific solution.

HYDROPHOBIC

-

A hydrophobic surface is a “water-fearing surface”. Upon contact with a hydrophobic surface water recedes to reduce contact with the surface. By receding, the amount of water in contact with the surface is reduced to a minimum. The surface repels the water, causing droplets to form.

The angle formed between the solid surface and the tangent to the curve of the liquid droplet is referred to as the contact angle. The greater the difference between the surface energy of the substrate and the surface tension of the liquid, the greater the contact angle and the easier it is to repel liquid droplets.

By definition a hydrophobic surface has a contact angle to water that is greater than 90 degrees.

-

Just comparing the contact angles of water to hydrophobic and super-hydrophobic surfaces you would easily think that having a super-hydrophobic surface would be better than a hydrophobic surface.

However, there are other types of properties that need to be considered in deciding between a super-hydrophobic and hydrophobic surface such as abrasion resistance, durability, and transparency.

Sometimes an abrasion resistant hydrophobic coating can offer more protection from water and moisture than a super-hydrophobic coating. If transparency is desired to protect against moisture, then a hydrophobic coating is generally more robust and less expensive.

-

ViriDyn’s hydrophobic surface coatings perform highly in the protection of Printed Circuit Boards, Ball Grid Arrays, Semiconductors, Consumer Electronics, Sensors and Lenses.

Conformal Coatings

VIRIDYN 101-X: a masking-optional,conformal coating offering industry-leading corrosion and tin whisker prevention.

Sensors and Lenses

VIRIDYN DX: optically transparent, abrasion and corrosion resistant coating for high-performance optical lenses, harsh environment sensors, and ruggedised electronics.

To learn more about how ViriDyn’s hydrophobic nano-coatings and surface treatments can support your conformal coating, consumer electronics, ruggedised electronics, sensors and lenses engineering requirements, please contact us.

-

VIRIDYN 101-X: a hydrophobic nano-coating used to protect electronics and fluidic devices from water, biofluids, oils, and similar exposures.

To learn more about VIRIDYN 101-X, click here or visit ViriDyn’s Hydrophobic Products page.

VIRIDYN RF: an innovative wipe-on, long-term durable, hydrophobic coating for flat panel antennas and SATCOM devices. To learn more about VIRIDYN RF, contact us.

If you have a technical challenge that could be solved with a hydrophobic coating or additive, contact us. We have either already developed it or can use our expertise and technology to engineer a specific solution.

OLEOPHOBIC

-

An oleophobic surface repels oil. An oleophobic coating generally has a contact angle to oil that is greater than 60 degrees. Oil and oily substances like fingerprints and grease are less likely to adhere to an oleophobic surface.

Therefore, oleophobic surfaces are sometimes called anti-fingerprint or easy to clean surfaces. Most cell phones and touchscreens now come with an oleophobic surface. These surfaces not only repel fingerprints they also have a slippery surface, this is due to the low coefficient of friction of the surface.

-

Coated membranes repel water and oil, while allowing the passage of air, gases, and sound. Membrane applications include filtration, venting, and diffusion barrier applications.

Venting membranes are used for:

Automotive (headlamps, electric motors, ABS brakes, gas tanks pressure sensors, engine oil sensors).

Healthcare (catheters, IV filter vents, suction-related apparatuses, and instruments).

Oil and Gas (petroleum filtration, fracking water organics cleanup and separation).

Other applications (vented packaging, gas sensors).

Since oleophobic coatings repel fingerprints they are widely used on all types of portable electronic that utilise touch screens, such as smart phones, tablets, and laptops. While some devices come with a factory applied oleophobic coating, these coatings may need to be reapplied after extensive use.

To learn more about how ViriDyn’s oleophobic solutions can support your filtration requirements, contact us.

-

VIRIDYN 101-M: an oleophobic nano-coating for membranes, vents, filters, and meshes.

To learn more about VIRIDYN 101-M, click here or visit ViriDyn’s Oleophobic Products page.

If you have a technical challenge that could be solved with an oleophobic coating, contact us. Other ViriDyn solutions are available with oleophobicity grades as high as 8, or we can use our expertise and technology to engineer a specific solution.